Shop by Category

Tubing Solutions with the M-WF385Xconnect

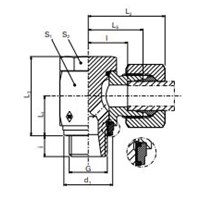

A Waltech tube former is a versatile machine capable of shaping steel and stainless steel tubing in sizes from 6 to 42 millimeters, making it ideal for a broad range of applications. Widely used across industries such as construction, agriculture, manufacturing, oil and gas, and transportation, Waltech tube formers are engineered to deliver leak-free, reliable performance, even under high-pressure and high-vibration conditions. Designed with durability and precision in mind, these tube formers meet the stringent requirements of industrial environments, helping to ensure safe and efficient operations where high-quality fluid transfer systems are essential.

.png)

These tube formers incorporate several advanced design features to enhance their performance:

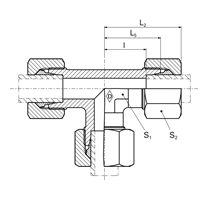

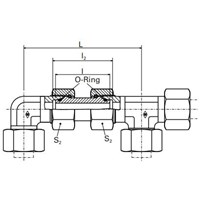

Patented Nose Design: Provides secondary metallic sealing, eliminating leakage risks.

Positive Locking Mechanism: Delivers reliability under extreme dynamic loads.

Locked-In Retaining Tube: Mitigates the risk of disconnection.

Optimized Center Area: Prevents overtightening, reducing the potential for leakage.

Soft-Seal Technology: Offers primary sealing for assured leak-free operation.

Aerospace

Manufacture and maintain aircraft systems, where precision-formed tubes are vital for fuel lines, hydraulic systems, and air conditioning systems.

Automotive

Tube forming systems are used for brake lines, fuel lines, power steering lines, and air conditioning systems. In the manufacturing of vehicles.

Power Generation

Providing precise quality tubes that are needed for boiler tubes, heat exchanger tubes, and other components.

Precision

Tube forming systems enable the creation of tubes with exact dimensions and tolerances, ensuring that they fit perfectly into their intended applications.

Consistency

consistent production of tube assemblies, the M-WF385Xconnect guarantees uniform performance across all tubes.

Efficiency

Resulting in significant time savings. This translates into quicker production times, reducing downtime in plants during maintenance or upgrades.

Customization

The ability to create a wide range of tube shapes and sizes, providing the flexibility to manufacture custom tubes for specific requirements

Contact Us

we are your partner in progress. We aim to exceed your expectations with our comprehensive range of services. Contact us today and let our team of experts provide you with the top-notch hydraulic solutions you deserve.

Custom Hydraulics and Design

242 Dick Beam Road, Cherryville

North Carolina 28021

P: (704) 347 -0023