Shop by Category

Screw-In Cartridge Poppet Valves: An Overview

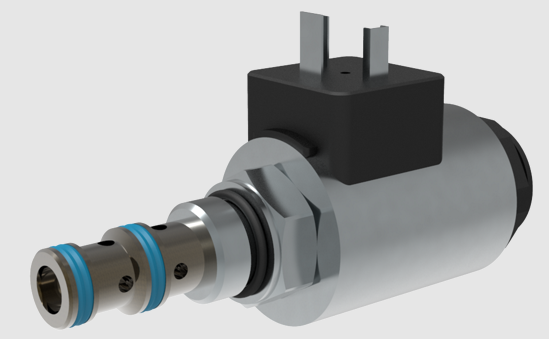

Screw-in cartridge poppet valves are hydraulic components used in fluid power systems. They're called 'screw-in' because of the way they're installed directly into a valve cavity or manifold, screwed in like a bolt, and 'poppet' because of the type of mechanism they use to control fluid flow. Now, let's dive deeper into the subject.

What Are Poppet Valves?

A poppet valve is a type of valve typically used to control the timing and quantity of gas or vapor flow into an engine. It consists of a hole, usually round or oval, and a tapered plug, usually a disk shape on a shaft, also called a valve stem. The portion of the hole where the plug meets is called the "seat" or "valve seat". The shaft guides the plug portion by sliding through a valve guide. In exhaust applications, a pressure differential helps to seal the valve and in intake valves, a pressure differential helps open it.

How Do Screw-In Cartridge Poppet Valves Work?

Screw-in cartridge poppet valves control fluid flow by moving the poppet away from the valve seat. When the poppet is moved away, fluid can flow through the valve. When the poppet is returned (usually by a spring mechanism), it sits on the seat, creating a seal that prevents fluid from passing.

The 'screw-in' design offers several advantages. Because they're screwed directly into the system's manifold, they often provide superior performance compared to other designs due to minimized fluid pathways and reduced potential leak points. They're also compact and straightforward to install and replace.

Applications

These types of valves are used in a wide range of hydraulic applications, such as mobile hydraulics, agricultural machinery, and heavy-duty industrial machinery. Their robust design makes them ideal for challenging operating conditions where high pressure, high flow rates, and rugged environments are encountered. They are commonly used in applications like directional control, pressure relief, pressure reducing, flow control, check, and logic element applications.

Screw-in cartridge poppet valves offer a compact, high-performance solution for fluid control in hydraulic systems. They're designed for ease of installation and maintenance, making them an attractive choice for a range of applications. As with all hydraulic components, it's essential to ensure that a cartridge valve is suitable for the specific pressures and flow rates of your system to ensure optimal performance and safety.